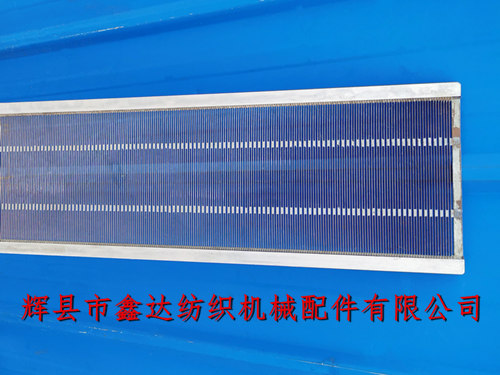

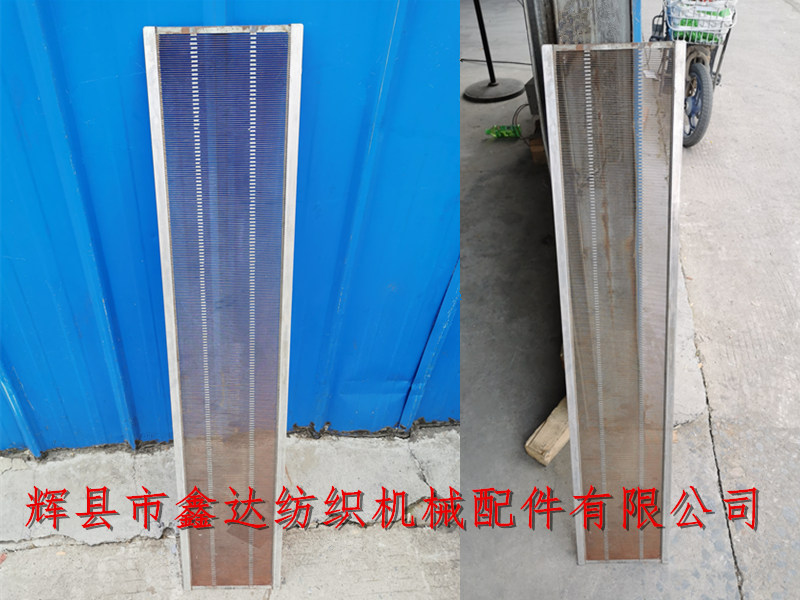

Our company specializes in providing all kinds of textile warping machine parts of reed, solder reed, special-shaped reed. The reed is mainly used for warp layering in warping process, which is convenient for forming shed when weaving. The warping machine parts of reed are made of aluminum alloy, thickened reed teeth, single reed lattice solder, with a height of about 20cm, and special specifications of textile hardware parts of reed Reed can be customized according to customer requirements.

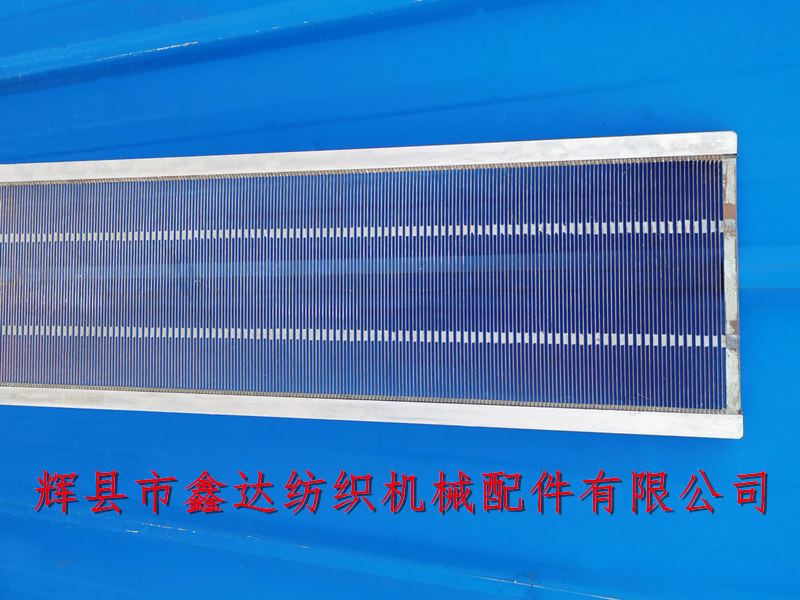

Split reed,Warping machine accessories,Textile split reed,The keel of the warping machine's slinger is fixed by steel wire, wound by iron wire, and the workmanship is solid and stable. The textile slinger is placed between the warping machine's frame and the main frame head, about 2 meters away from the frame, and about 1 meter away from the main frame head (please adjust appropriately according to the gate size of the warping machine). This placement can reduce the warp wear and friction, and reduce the occurrence of warp interruption in the warping process.

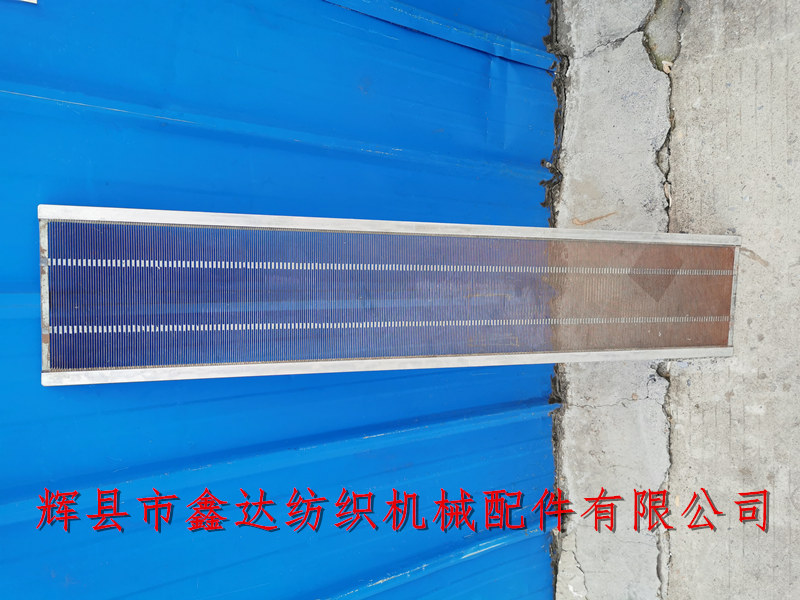

The length of the split reed in the figure above is 1.2m. The support shape of the split reed needs to be changed according to the total number of warps during warping. For example, when sizing warping, the arc-shaped design will be adopted. This design is mainly due to the large number of warps required for one warping forming, the wide contact range and large density of the split reed,Warping Machine Reed Parts.

Warping machine accessories,Split reed,Warping machine accessories,Textile split reed - reed production and processing, reed wholesale and product details please contact our company for consultation, 20 years of professional textile accessories suppliers sincerely welcome your presence!