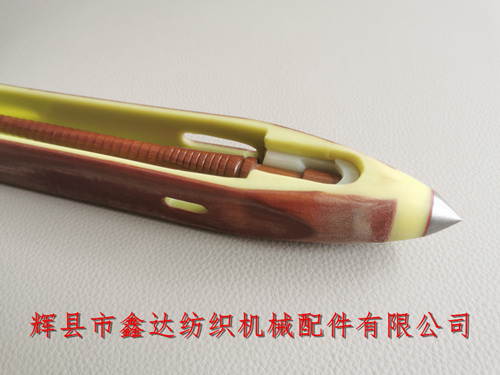

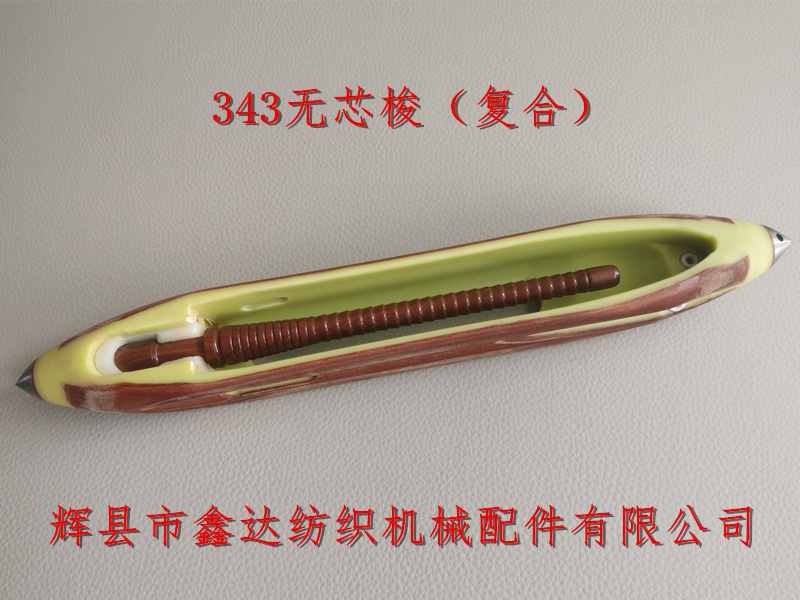

Huixian Xinda Textile Machinery Parts Co., Ltd. provides a 13½ inch composite shuttle with three ceramic eye photoelectric coreless shuttle. The total length of the shuttle is 13.5 inches (343mm), and the two sides of this coreless shuttle have added composite fabric layers. The weft detection method is photoelectric induction, and the shuttle cavity does not have a shuttle core, so it is called a photoelectric coreless composite shuttle. The outer width of the shuttle bottom is 45.5 millimeters, the total height of the composite shuttle body is 35.3mm (white nylon clamp position), the inner cavity width is 30.8mm, and the depth is 29.7 millimeters.

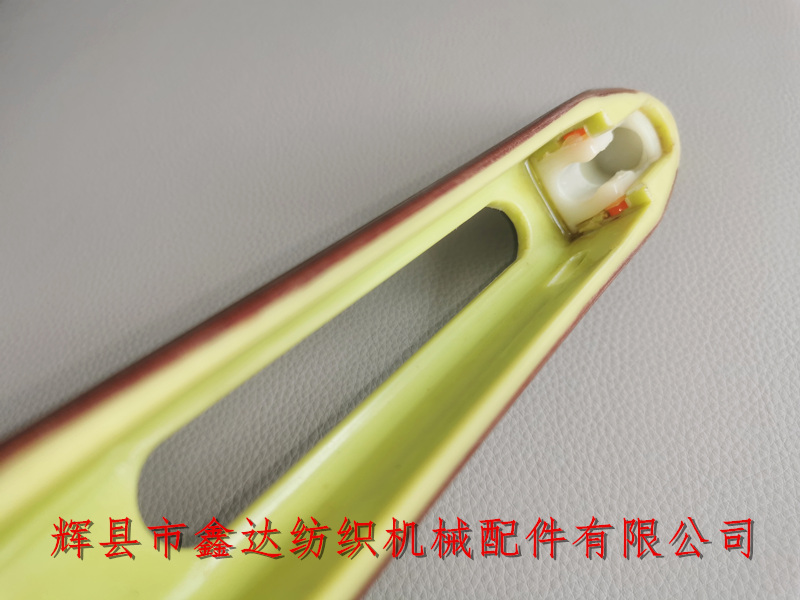

Textile equipment - There are photoelectric weft detection holes (rectangular in shape, as shown in the above picture) on both sides of the 13 half inch composite shuttle. The weft detection groove below is 8.5 millimeters wide and 40 millimeters long. The weft yarn guide surface is at a 90 degree angle to the shuttle bottom; The inner width of the other side's weft hole is 6.5 millimeters and the inner length is 20mm, forming an angle of 86 ° with the bottom of the shuttle. The neck diameter of the 230mm coreless tube used in conjunction is 12.5 millimeters, and the neck length is 21.5-22 millimeters; The circular diameter of the flat head of the warp tube is 17.7 millimeters and the length is 20 millimeters.

The nylon clamp of the shuttle is edged, with orange elastic cylinders on both sides of the ears, used to tighten the neck of the coreless tube. The bottom of the PU clamp is glued together, and the tail of the upper plane has a raised crescent shaped blocking block to maintain the correct installation position of the coreless PU clamp. The weight of this composite coreless shuttle is 291 grams/pcs. The shuttle is divided into left and right hands, with 50 pcs per box (for the same hand).

The above picture is a bottom photo of the photoelectric composite coreless nylon shuttle. The width of the opening groove below is 18 millimeters and the inner length is 134 millimeters. Its main function is to easily lift the weft tube when replacing the coreless tube with fingers from below. In addition, there is a curved groove with a width of about 15 millimeters at the bottom of the shuttle, which is used to export the weft yarn from below.

The front of the shuttle body is equipped with three ceramic eyes, which are arranged in the same way as the conventional three ceramic eyes. The groove for installing the ceramic eyes on the bottom has a width of 12 millimeters, an inner length of 27 millimeters, and a depth of 10 millimeters. If you need to purchase three ceramic eye composite shuttles, 13½ inch coreless shuttles, 13.5-inch photoelectric shuttles, or other photoelectric coreless shuttle textile equipment, please contact Mr. Yang from our company for consultation.