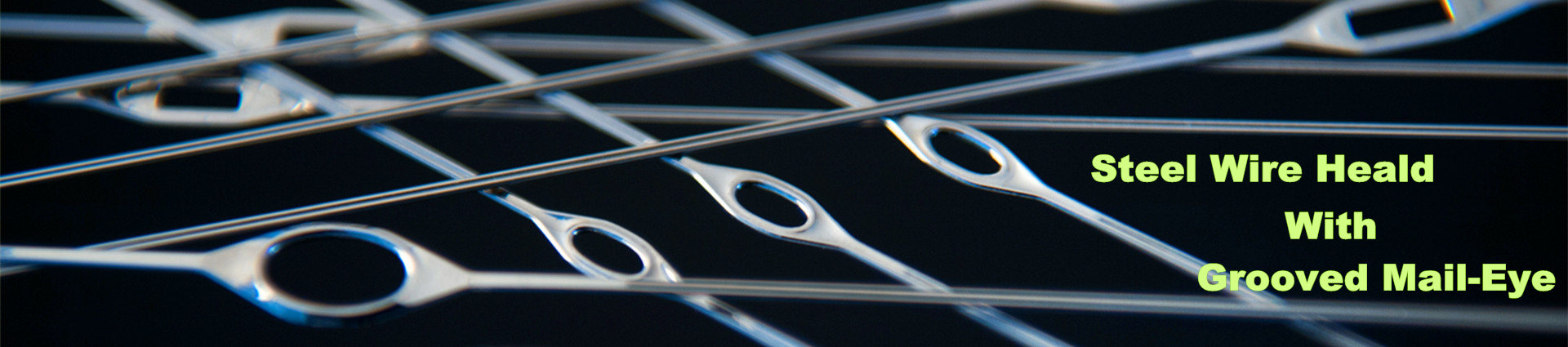

Huixian Xinda Textile Machinery Parts Co., Ltd. provides 15"*27G*1080R Heddle Grooved Mail-Eyes. The inner length of the textile equipment steel wire heald is 380mm, and the inner cavity dimensions of the heddle ears at both ends are 15mm in length and 5mm in width. The diameter of a single wire welded side by side is 0.4mm. The middle hole of the weaving equipment steel wire harness is embedded with a 1080R type Washer (ring), and the total thickness of the sliding ring position is 0.8mm.

There are various specifications for the soldering wire of textile machines. Under normal circumstances, a 0.4mm steel wire should be matched with a 355R (inner width of 2.3mm, inner length of 4.8mm) washer, while a 1080R is a large hole washer (inner width of 4mm, inner length of 6mm), generally matched with a steel wire with a diameter of 0.6mm or 0.7mm.

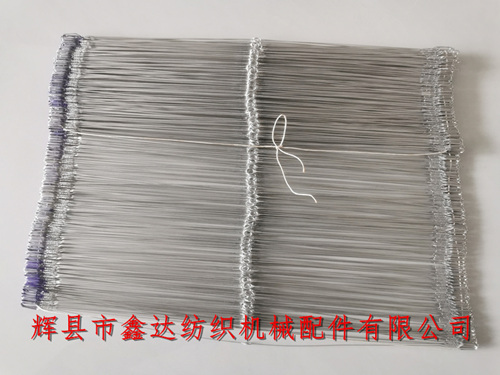

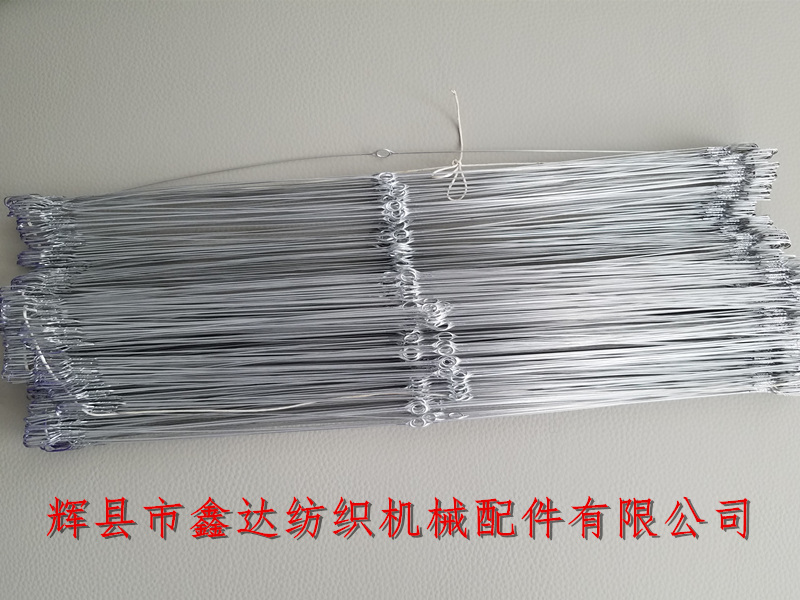

The packaging for the flanged wire harness with tin welding is 500 pieces per pack, with a weight of 0.5 kilograms per pack and a quantity of 15000 pieces per box (30 packs). The angle between the harness eyes of the weaving machine harness and the heddle ears at both ends is 45 degrees.

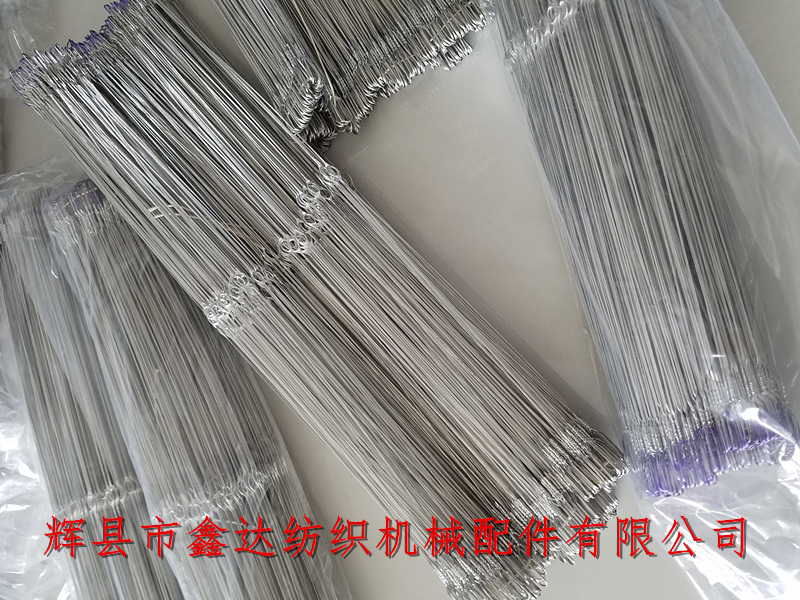

The above picture is a real shot of 15"*27G*1080R wire harness. The 0.4mm specification of steel wire corresponds to an imperial size of 27G, so this specification of steel wire harness can also be labeled as: 15"*27G*1080R, Among them, 15"; It refers to a length of 15 inches, which is 380mm.

For textile manufacturers, weaving factories, and trading groups who need to purchase 15"*27G*1080R steel wire mesh [15"*27G*1080R Heddle Grooved Mail-Eyes equipment], or for information on other parameters, dimensions, etc. of steel wire mesh, textile equipment, weaving mesh, soldering mesh, and domestically produced Heddle Grooved Mail-Eyes, please contact Manager Yang of our company for consultation.