GA615,1515 Automatic Loom Introduction

Brief introduction of GA615 and 1515 automatic looms (1) machine use and application range

The machine is mainly suitable for weaving plain cotton fabric, twill cotton fabric and general chemical fiber fabric. If the multi arm heald lifting device is added, the complex fabric can be knitted. Woven fabric of plain to 16 fabric.

(two) technical characteristics

1.the type of spindle is not stopped, automatic shuttle change type.

2.hand to the left hand car and right hand car.

3.reed width

(1) plain weave: 1350mm (56 inch loom), 1500mm (63 inch loom), 1600mm (67 inch loom), 1800mm (75 inch loom).

(2) dobby: 1350mm (56 inch loom), 1500mm (63 inch loom), 1600mm (67 inch loom), 1800mm (75 inch loom).

4.crank shaft speed: 160-190r/min (56 inches), 155-180r/min (63 inches), 150-170r/min (67 inches), 145-160r/min (75 inches)

5.chest beam height: 838mm

6.shuttle box number: 1X1

7.the angle between the reed and the shuttle board: 86.5 degrees

8.spindle storage capacity: 10

9.beam flange diameter: 495mm (large disk 550mm).

10.through the disc space: the most wide 1380mm (56 inch loom), 1555mm (63 inch loom), 1656MM (67 inch loom), 1860mm (75 inch loom).

11.full roller roll diameter: 300mm.

12.motor speed: 960r/min.

13.motor power: 0.8KW.

14.motor type: FO-53-6 (left and right) type or FO3-50-6N type.

15.Electrical switch: 1515-DZ4-25/330 (4A) button switch. GA615--LA20-2H button switch.

16.Integrated magnetic starter: QZ73-4G.

17.machine size:

Width: 2696mm (56 inches), 2866mm (63 inches), 2968mm (67 inches), 3171mm (75 inches).

Depth: 1656mm.

Height: 1540mm (plain), 2250mm (dobby)

18, machine weight (excluding motor)

56 inch loom: about 940KG (plain) and 1140KG (dobby).

63 inch loom: about 1000KG (plain) and 1200KG (dobby).

67 inch loom: about 1025KG (plain) and 1225KG (dobby).

75 inch loom: about 1100KG (plain) and 1800KG (dobby).

(three) drive mechanism;

1.drive mode: single motor V-belt drive.

2.control mode: one side switch handle control clutch and brake device.

3.clutch type: cone friction disc.

4.brake type: steel belt brake.

5.wheel shaft and crank ratio 1:2.

(four) principal bodies and their specifications;

1.warp let off mechanism

(1) type: semi active and semi negative automatic let off, automatic adjustment of warp tension.

(2) beam axle diameter: 110mm

(3) - disc diameter: 495mm, 550mm.

2.Break through parking device

(1) type: front and back swing, mechanical menopause.

(2) gear rod movement cycle: crank shaft rotation 2 times.

(3) number of menopause tablets: 4 columns.

3.shedding mechanism

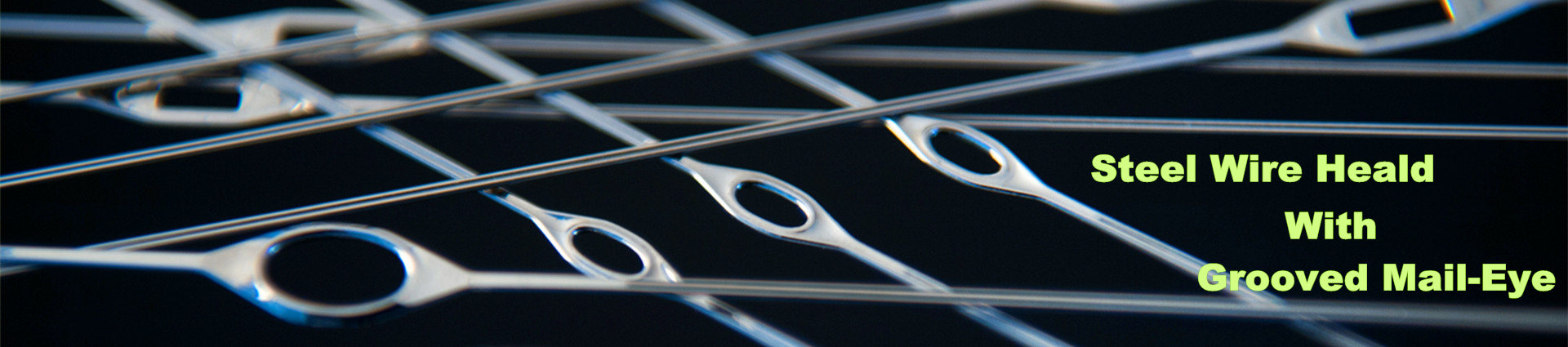

(1) type: inner disc, top roller, heald, heald opening.

(2) tappet shaft diameter: 42mm.

(3) heald frame number: 2 page heald frame (convertible twill tray to 5 pages or refitted dobby lifting device 16 pages).

4.shuttle throwing mechanism

(1) type: lower shuttle.

(2) the shuttle size: length 343mm (13.5 inches), width 44.5mm, high 33.5mm (left hand).

(3) skin knot type: movable skin knot.

(4) skin knot size: long 105mm, width 30mm, high 32mm.

(5) diameter of shuttle rotor: 76mm.

5.beating up mechanism

(1) type: crank shaft, beating with hands.

(2) diameter of crank shaft: 40mm.

(3) radius of crank shaft: 76mm.

(4) two crank center distance: 1540mm (56 inches), 1714mm (63 inches), 1816 (67 inches), 2019mm (75 inches).

(5) hand type: bushing type hand.

(6) hand length: 289mm.

(7) hand bolt diameter: 25mm.

(8) hand rocking center to center distance: 685mm.

(9) rocking shaft type: whole root.

(10) shaft diameter: 38mm.

(11) reed type: wooden structure.

(12) the length of the shuttle board is 1423mm (56 inches), 1699mm (63 inches), 1597mm (67 inches) and 1902mm (75 inches).

(13) box bottom plate length: 581mm side 600mm side switch, the shuttle magazine.

6.Warp protector

Type: movable reed.

7.Take-up mechanism

(1) type: seven gear intermittent take-up.

(2) weft density range: 16-32 /cm.

(3) diameter of thorn roller: 127mm.

(4) diameter of distributor roller: 32mm.

(5) cloth roller diameter: 95mm.

8.Extension device

(1) type: single row copper stab ring roller type.

(2) number: a group of left and right.

(3) shearing hammer: the impact of the reed block on the shearing force.

9. Self stopping device for breaking weft

(1) type: weft cam control side side weft fork or point peck weft insertion.

(2) coiling and unwinding device;

10.weft filling device

(1) type: automatic shuttle change type.

(2) the shuttle magazine: vertical in-line.

(3) spindle storage capacity: 10 handles.

(4) change shuttle induction device: use probe change shuttle induction device (for low requirement fabric, also can use weft fork to change shuttle induction device).

(5) shuttle changing safety device: when the shuttle changing mechanism fails, stop immediately and avoid mechanical damage.

(6) no shuttle, shuttle side parking device: Suokunei shuttle or shuttle position on the side, immediately stop automatically.

(7) prevent weft insertion device: avoid defects such as burrs and double weft, and improve fabric quality.

Five, the main equipment specifications

1.The length of the weft pipe is 180mm, and the head diameter is 27mm.

2.reed

Total length: 1394 (56 inches), 1568mm (63 inches), 1669mm (67 inches), 1873mm (75 inches).

Gao: 120mm.

3.heald length: plain or twill 305mm, dobby 330mm.

4.menopause film: long 120mm, wide 11mm.

5.triangle belt: A2286.

From"GA615 Automatic Loom Parts Atlas"