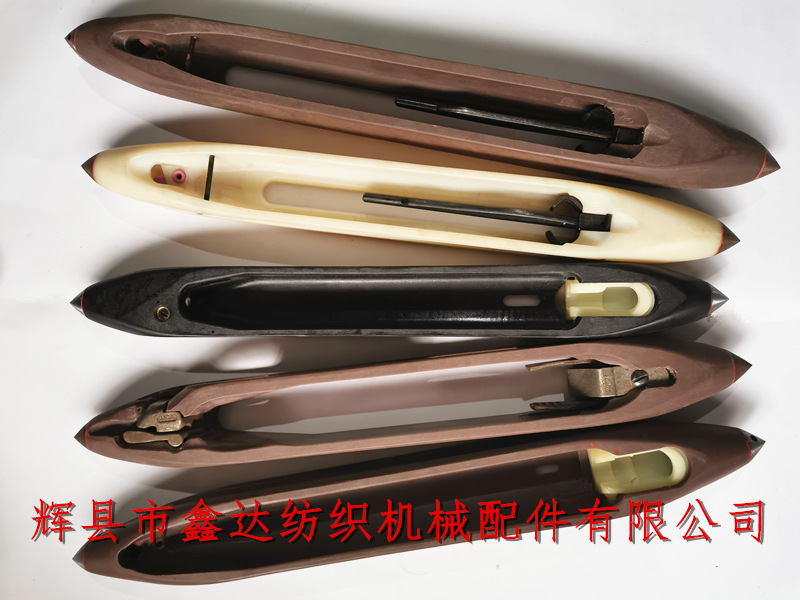

Size And Use Of Large Belly Long Cavity Nylon Shuttle

The large belly long cavity nylon shuttle is mainly used for weaving fabrics with thicker yarn counts. The weaving of products such as jute, asbestos, PP plastic flat silk, and heavy-duty canvas cannot be separated from the use of the large belly long cavity nylon shuttle. As an effective carrier of weft yarn, the capacity of the inner cavity (also known as the shuttle cavity) can to some extent affect the weaving cost. The dimensions of the nylon shuttle from top to bottom are as follows:

1、 Long chamber shuttle: 430mm * bottom outer width 44mm * shuttle height 33.5mm

2、 Small head shuttle: 393mm * shuttle bottom outer width 42mm * shuttle height 32mm

3、 TS-9 shuttle: 390mm * shuttle bottom outer width 42mm * shuttle height 31.7mm

4、 Automatic tube replacement Shuttle: 403mm * outer width of shuttle bottom 47.7mm * shuttle height 35mm * shuttle height 33mm (on the weft slot side)

5、 Coreless large belly shuttle: 415mm * outer width of shuttle bottom 47.7mm * shuttle height 39mm * shuttle height 38mm (on the weft side). There is a difference in height between the two sides of shuttle 4 and shuttle 5.

Nylon shuttle with narrow shuttle cavity is generally used in foreign looms, such as shuttle looms produced in Russia, Japan and India. After proper modification of loom design, weaving efficiency can be improved. Generally, small shuttle heads are used. Due to the reduced width of the shuttle body, there are strict requirements for the angle of the shuttle box and later maintenance, as well as restrictions on the position of the center of gravity of the shuttle itself, which can ensure the stability of the shuttle during high-speed flight.

According to different types of fabrics, the position of weft yarn leading out from the shuttle also varies, which can be generally divided into side leading out and shuttle bottom guiding. Relatively speaking, using side weft insertion is more common.

The bottom position of the large belly shuttle adopts a double flow groove design, which can reduce the air resistance during nylon shuttle flight and stabilize the shuttle posture. The large belly shuttle has a large yarn capacity, reduces the number of shuttle changes during operation, reduces the waste of weft yarn return, reduces the labor intensity of the blocking workers, and improves the fabric weaving effect.